We are so proud to be using recycled plastic fabric in our suits. Our suits are not only ethically made, but are as eco friendly as they can be. Our suits are made from Carvico Vita fabric, which is made up of 78% ECONYL recycled nylon yarn. We’ve done the research on how Carvico Vita make their fabric and the pros and cons so you don’t have to.

Read below for the ins and outs. We cover how the fabric is made, if it’s safe on the skin, if it’s environmentally friendly and what the downsides are. We hope you enjoy!

Carvico Vita fabric

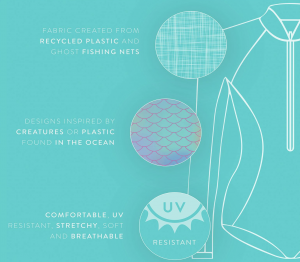

Carvico Vita is a recycled plastic fabric made in Italy from two yarns – 22% elastane and 78% recycled nylon. These yarns are woven together to create a high quality fabric with sun cream, chlorine and piling resistance, UV protection, two-way stretch and an ultra flat soft surface.

Carvico Vita is certified as STANDARD 100 by OEKO-TEX®. This is one of the world’s best-known labels for textiles tested for harmful substances. Some people speculated that recycled plastic fabrics may not be safe against the skin due to BPA and other substances found in plastics. We can assure you that Carvico Vita (and most recycled fabrics on the market) are free of these.

The nylon is 100% recycled and created by an amazing company called ECONYL.

What’s ECONYL?

So let’s talk about ECONYL – the real superstar!

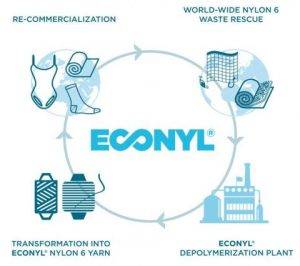

ECONYL is the recycled nylon fibre produced by parent company, Aquafil. Although nylon can be recycled it is very difficult. Aquafil is the only company doing so on a large scale.

CEO, Giulio Bonazzi says himself, “We vastly underestimated the difficulty of this operation. Fortunately because if we had known everything beforehand I don’t know if we would have started this incredible journey.”

Aquafil recycles nylon waste into new nylon fibre. The new nylon fibre is chemically identical to virgin (oil based) nylon. It’s 100% recycled material and 100% recyclable!

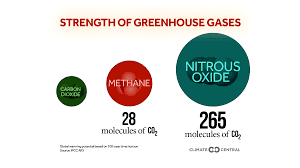

Creating ECONYL has an estimated 80% lower global warming impact compared to virgin oil based nylon. Traditionally nylon is made from a fossil fuel derivative – hexamethylenediamine. With large amounts of water and nitrous oxides being produced in the process.

To create ECONYL there are 6 major steps:

- Waste Rescue

- Waste Preparation

- Depolymerisation

- Polymerisation

- Transformation

- Commercialisation

ECONYL waste rescue

In terms of post consumer waste there are two main streams: fishing nets and carpets.

Aquafil have developed a whole supply chain to collect nylon waste which would otherwise end up in landfills. This nylon waste would otherwise take years to degrade into harmful microplastics.

The fishing nets are retrieved from the oceans by Healthy Seas, a non-profit co-founded by Aquafil. So far they have retrieved 510 tonnes of fishing nets from the oceans to be recycled into ECONYL. Each net could otherwise remain in the ocean for over 100 years entangling and choking marine life. They also partner with industrial fisheries and fish farms so that their damaged nets become recycled.

Aquafil reclaim thousands of tonnes of waste each year!

ECONYL regeneration

The waste is then sorted, cleaned and shredded to recover all the nylon possible. Then through a miraculous purification process the nylon waste is chemically broken down into its constituent parts (depolymerisation). Finally being polymerised back into pure nylon – identical to its virgin oil derived ancestor.

This nylon is then transformed into a thin thread, stretched out to give it elastic properties and spun into either a carpet yarn or a softer textile yarn. It’s now ready to be woven into a recycled plastic fabric elsewhere, like Carvico Vita.

Problems with recycled plastic fabrics

Is Carvico Vita perfect? No, but what is? We have been doing a lot of research into the most sustainable fabrics out there for our swimwear, but also for t-shirts and bags in the future. One thing we have learnt is that the best option depends on your values.

Global warming, microfibres, ethics, toxic outputs, water usage, durability etc.

For swimwear a synthetic fabric is the best out there for performance. Cotton or hemp simply will not work in a swimsuit. Our own option is a synthetic (a.k.a. plastic) fibre. Of those available the best option is a recycled plastic fabric like Carvico Vita.

Even if we were making a bag or a t-shirt we found that recycled nylon uses far less water than cotton, uses less land, has lower global warming impact, uses less energy to produce and lasts longer!

The downside though is that nylon is plastic. In reality not all nylon will be recycled. Also during its lifetime it can leach plastic microfibres during washing or being in the ocean. Although there are ways you can reduce the impact during washing. Hand washing is best and you can invest in a microfibre catcher for your washing machine too.

Read more in our blog: The Problem with Microfibres

Overall…

We are super happy to be using such a revolutionary fabric for our suits. One day, we hope that all swimwear and activewear will be made of recycled fibre.

We are glad that we can create high quality, durable suits without compromising on our priority – the health of the oceans.

If you have any questions please get in touch!